The Need

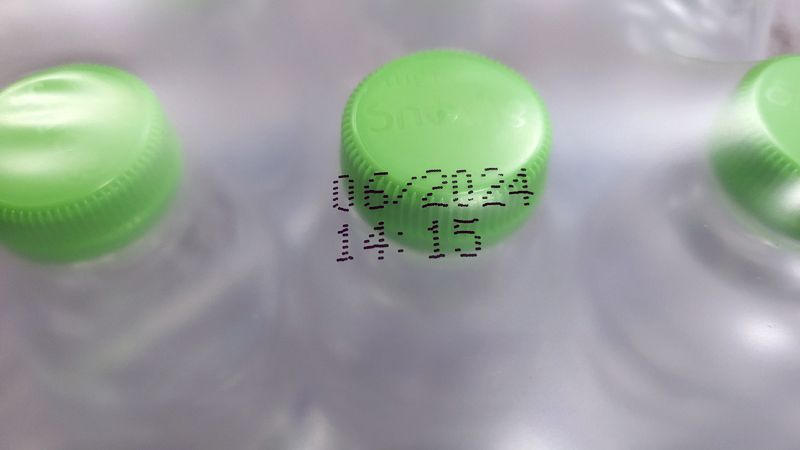

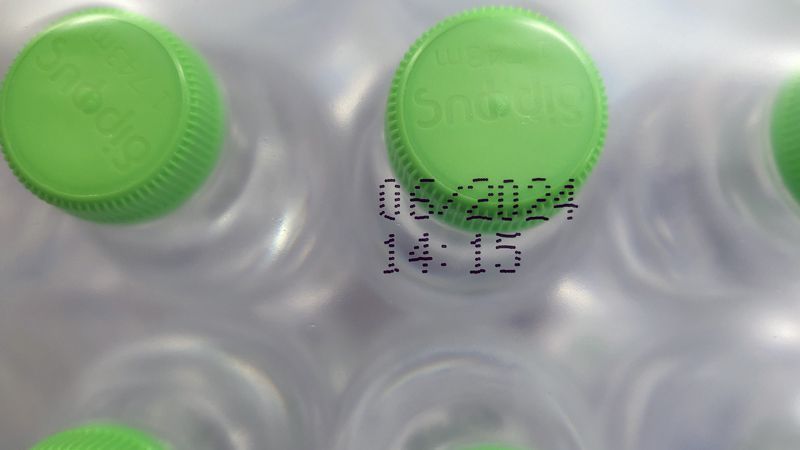

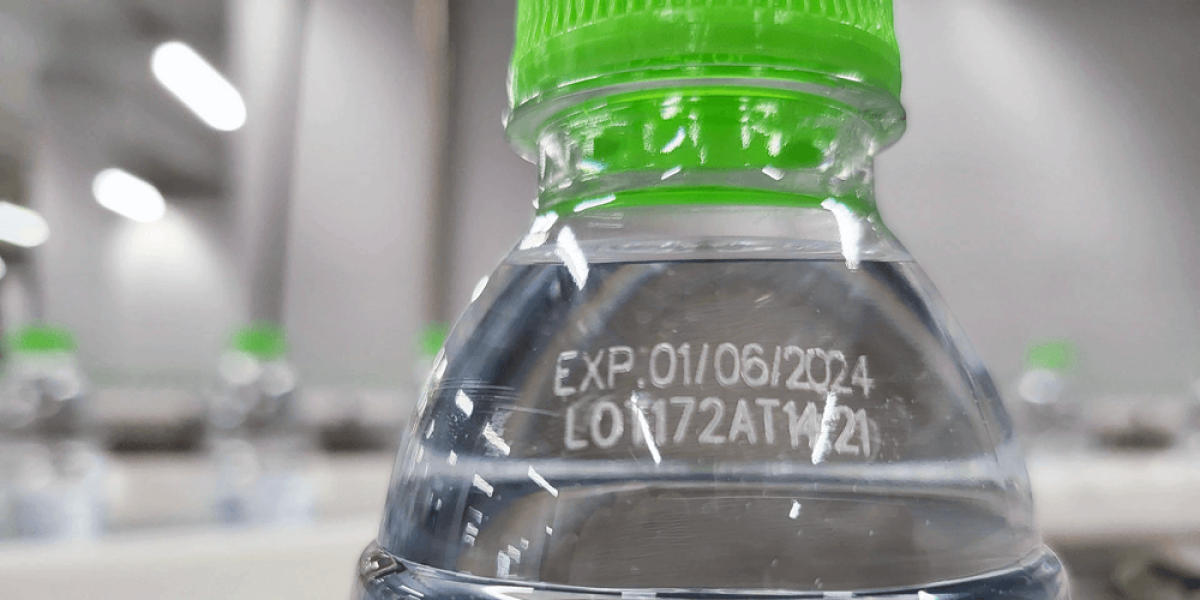

To achieve high quality printing at high production speeds and an elegant result in the coding of its bottled water, DIRFYS SA, a leading water bottling company, reached out to us to provide a reliable solution to print variable data (such as expiry date and production code) directly on the bottle packaging.

The Solution

Responding to this need we installed two industrial Domino laser technology printers for the coding of the primary packaging (PET botthles), as well as an inkjet technology industrial printer for the coding of the secondary packaging (shrink wrapped bottles).

In addition to the industrial laser printers, we also designed and installed a bracketing kit, a special safety cage on the print heads to protect the operators as well as special devices for extracting fumes created during operation of the laser printers.

Industrial laser printers can support printing of variable information on PET bottles at speeds of up to 40,000 bottles/hour, require no consumables to operate, offer high reliability of non-stop operation (99.99% uptime) and enable interfacing with IT factory systems.

The Benefits

- Minimal to zero printing costs of laser printers, given no consumables (inks) are needed

- Fast printing speeds

- Reliable non-stop operation

- Quick and easy switchingof production programs

- Modern and environmentally friendly technology

- High quality printingand an elegant result in the markingof the products

- Ability to interconnect with factory information systems

Click on the photographs for a larger view:

If you are interested in a similar solution, please fill out the contact form below or email us at

Food / Beverages