The Need

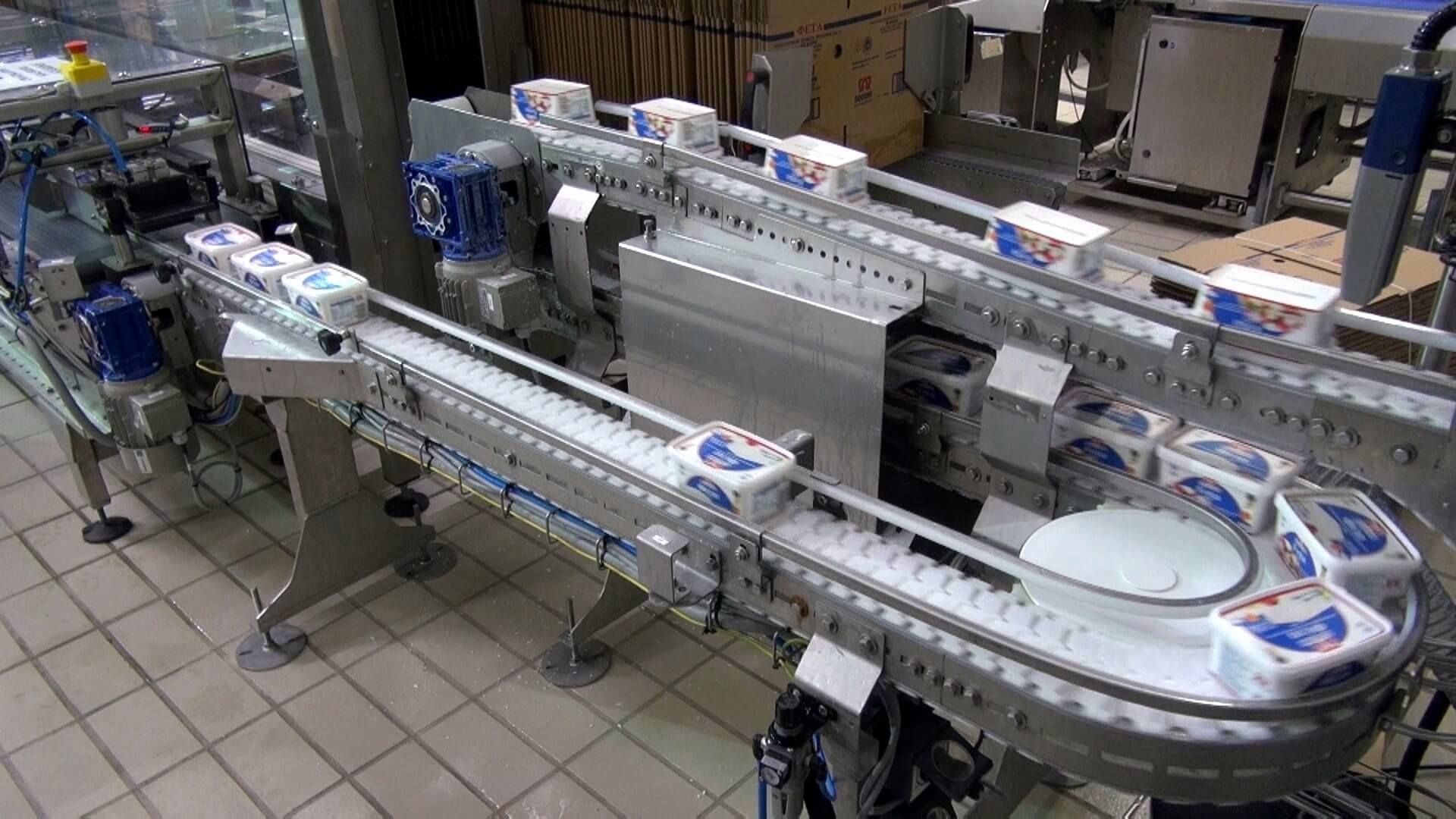

DODONI SA was looking for a solution to automate the case packing of plastic cheese containers and achieve increased productivity and optimal utilization of the existing space.

The Solution

We designed and offered a complete and fully automated solution that met the needs of the company and includes:

- Conveying system for plastic containers

- Carton forming

- Grouping and pattern Forming for three lines

- Case packing of groups of plastic containers

- Sealing the carton with packing tape

- Managing through a control panel different products and patterns

The system accommodates for future upgrades to meet future needs. Finally, the solution is accompanied by a complete security system, which guarantees user safety and CE certification.

The Benefits

- High productivity

- Reduction of operating costs

- Reliability and minimal maintenance needs thanks to the tested design and the excellent quality of construction

- Durability in the very demanding working environment thanks to the stainless steel implementation of the system

- Flexibility and scalability (possibility of future upgrades & modifications for new lines, new packaging, etc.)

- Fast product changeover thanks to the ease of settings and the short time required

- Connectivity with the company’s IT systems

- Optimal use of resources (space, human resources, existing equipment)

- Minimal handling requirements and error minimization

Click on the photographs for a larger view:

If you are interested in a similar solution, please fill out the contact form below or email us at

Industries:

Food / Beverages

Food / Beverages