The Need

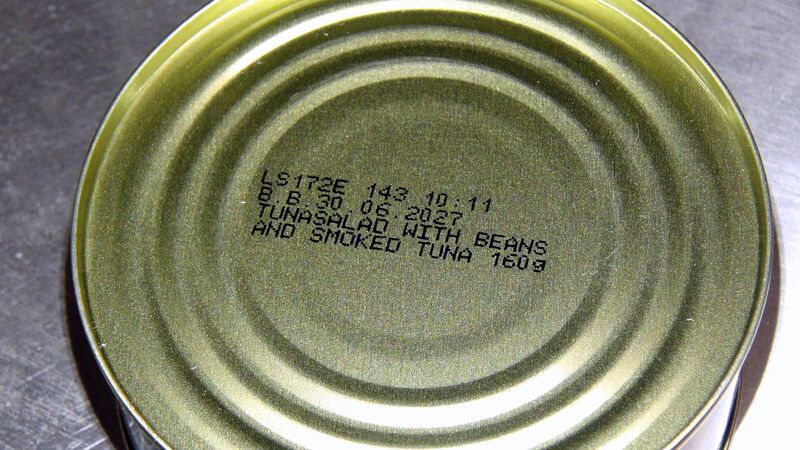

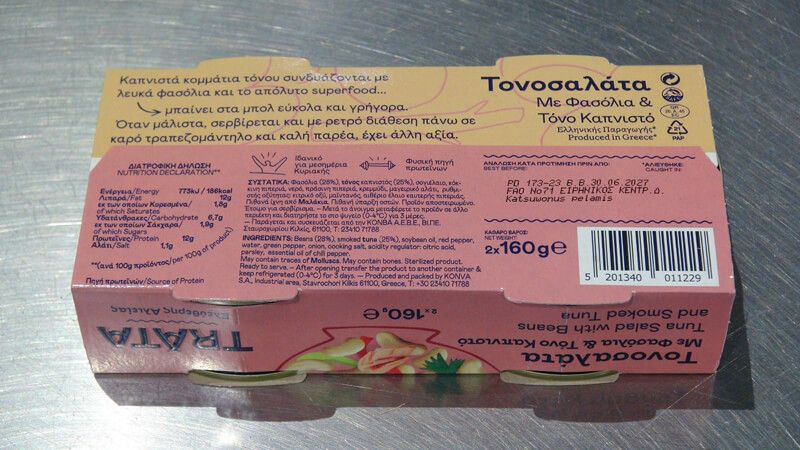

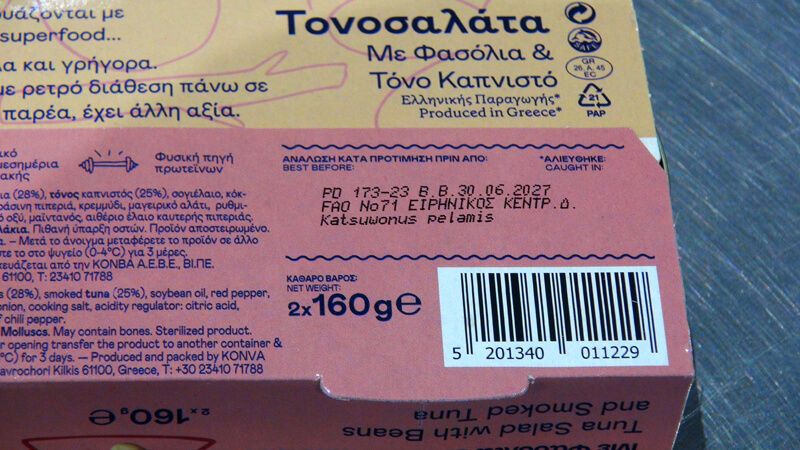

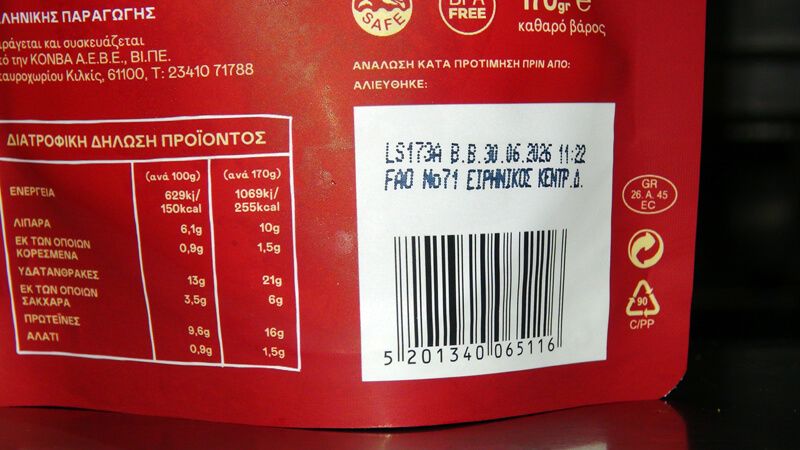

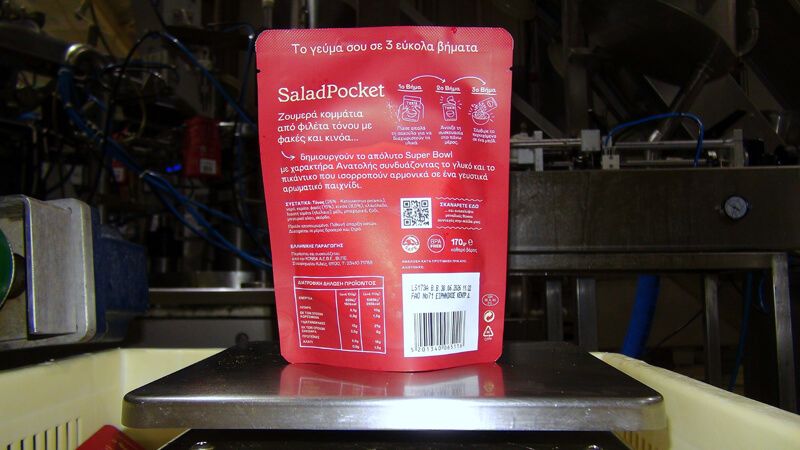

KONVA SA, a state-of-art fish processing factory handling many codes for various markets, needed a flexible and modern coding solution to print variable data on its primary and secondary packaging.

The Solution

To meet the need for coding on primary packaging we installed one of the most modern industrial inkjet technology code printers of Domino. The solution provides online management of variable information sent to print in production.

When it came to secondary packaging, an industrial inkjet on-demand code printer, also from Domino, was installed. With this solution, the self-adhesive labels used to mark the cartons are not needed anymore since all variable information is printed directly on the packaging.

The Benefits

- Increasing productivity with the use of modern equipment

- Remote control, connectivity and monitoring of systems with special software.

- Reduction of errors due to online management of variable codes

- Reduce operating costs resulting from wasted or destroyed consumables

- Immediateness and flexibility in adapting to different products and production orders

- Full alignment with ISO 14001 for environmental management by eliminating the use of stickers to mark cartons

Click on the photographs for a larger view:

If you are interested in a similar solution, please fill out the contact form below or email us at

Food / Beverages