The Need

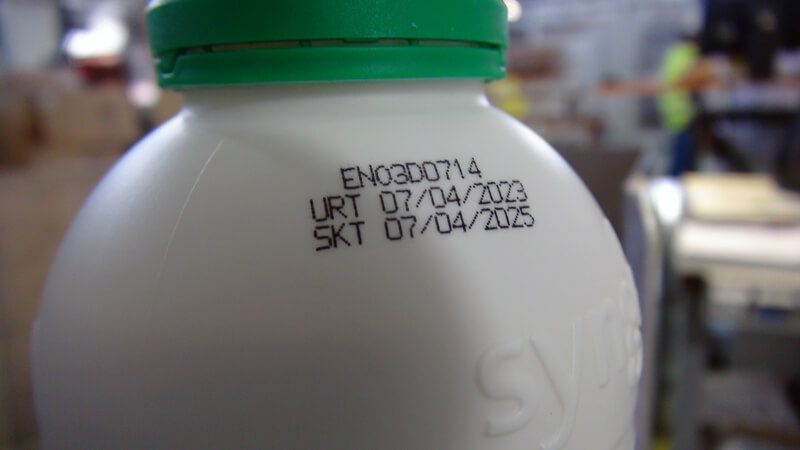

Based on the principles of Industry 4.0, Syngenta wanted to fully automate all the packaging processes of its 7 production lines, i.e. the coding & marking, quality control processes and rejection of non-compliant products, labekling, product handling, case packing, palletising and stretch wrapping pallets with stretch film while at the same time ensuring full traceability of the produced goods, item level to pallet (full serialization & aggregation track and trace).

The Solution

We designed and implemented an integrated end-of-line system for all 7 production lines providing all the mechanical equipment required and participating as an integrator in the implementation of the full traceability project.

The integrated automatic packaging system works as follows:

First, the production order is automatically downloaded from the ERP, with which the system is interconnected, and its execution begins. After the product is introduced in its primary packaging, its marking begins with the printing of a unique 2D code with UV ink (invisible) on its lid, which, at a later stage, is used for the aggregation of the items in boxes.

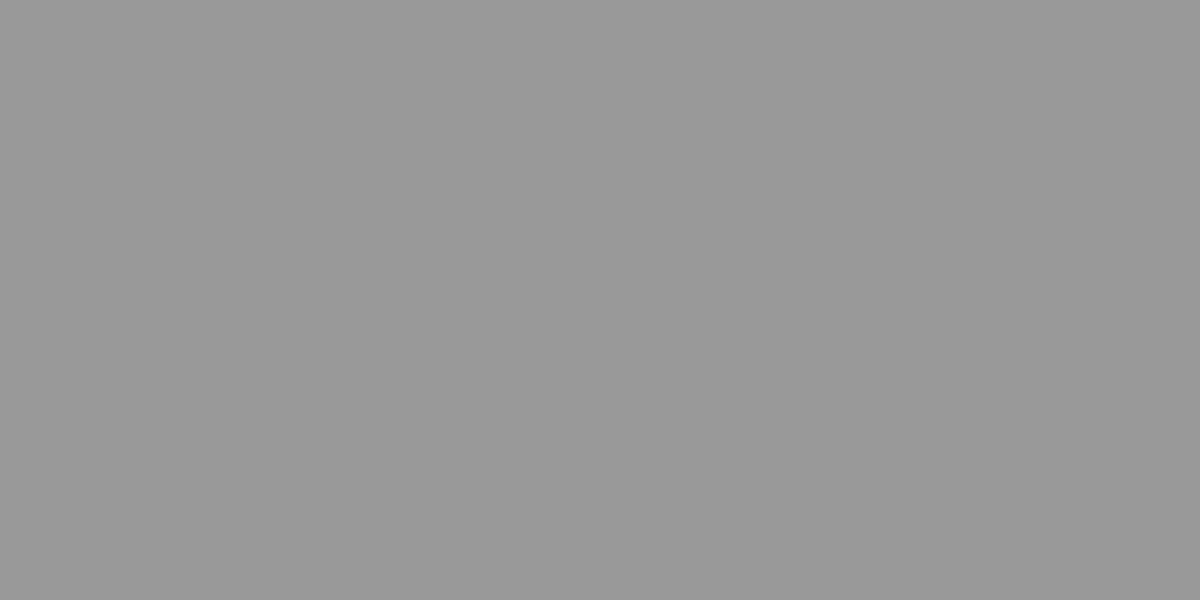

The bottle or drum products are then automatically transported and driven to a device for automatic weighing and control of their weight and rejection of non-compliant ones. The products that pass the first quality check (weighing), move on to the next stage, the printing of variable information (2D & human readable information) and the automatic labelling of their packaging, either wrap around, or on two sides, as well as checking with a camera the correct printing and readability of this information.

The products are then taken to the next stage, where a camera scan links the unique code printed with UV ink on the package lid with the unique code printed on the package label. This information is used later to match uniquely marked items with the boxes that contain them (aggregation).

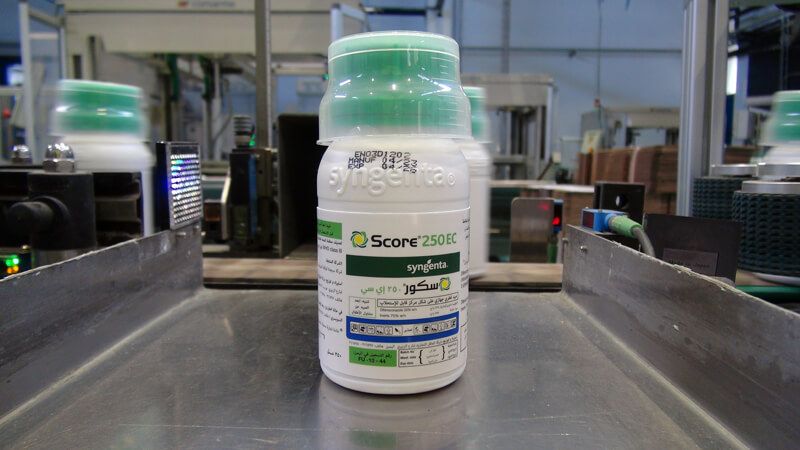

Moving on to the automatic packaging stage we implemented a fully automatic carton formation and case packing system which also includes a stage for reading, verifying and mapping (case aggregation) unique UV codes printed on each lid to cartons Each carton is then automatically transported to the exit of each production line, to be picked up by a palletizing robot. As it moves, the box is weighed, checked and automatically rejected if needed. The carton is then labelled by a Domino Print & Apply printer with info such as item code and description, production order, batch, production date, quantity, unique carton number, etc. After labelling, a camera checks that the label is correctly printed, applied and is readable.

The cartons then arrive at the waiting point to be picked up by the robot for palletizing. Each carton label is re-checked by camera and the unique carton code is mapped to the pallet built by the robot on the corresponding production line. In this way, cartons placed on each pallet from each production line can be fully tracked and traced (case to pallet aggregation).

As soon as the pallet building is done, the pallet moves to the stretch wrapper and finally to the pallet labeller. At this point the pallet is identified by reading the carton labels using a camera. The pallet label is printed and applied and includes all the dynamic data of the production order executed, the unique SSCC (Serial Shipping Container Code) of each pallet has been assigned to the unique codes of the cartons it contains and each carton in turn has been assigned to the unique codes of the items it includes (full aggregation).

Finally, the system returns the information of the full aggregation to the ERP and each produced pallet appears in real time in the ERP and ready for loading.

The Benefits

- Full automation of the management processes of all packaging levels

- Central management of marking from item to pallet

- Quality assurance of products, boxes and pallets

- Automation and reduction of setup and changeover times

- Facilitation and time saving of logistics processes

- Full traceability as a result of the full aggregation process (item - box - pallet)

Click on the photographs for a larger view:

If you are interested in a similar solution, please fill out the contact form below or email us at

Plastics / Chemicals / Detergents

Codes Verification, Serialization & Aggregation, Weighing & Labeling, Checkweighers, Robotic Palletizing, Automatic Case Packing, Integrated Packaging Systems, Case Erectors / Sealers, Tracer Factory, Connected Automation Systems, Automatic Handling & Sorting, Continuous Inkjet Printers, Print & Apply Systems, Wrap Around Labellers