- Home

- Solutions / Products

- Processing & Filling

- Tablet / Capsule Automation

- Counting & Filling

Bottle Unscrambling / Air Cleaning

For the preparation of bottles prior to filling, Arcon offers different capacities automatic Bottle Unscramblers & Cleaners. They sort and align bottles at speeds of up to 300 containers per minute. The containers are also inverted and cleaned – first with filtered (by pharmaceutical grade filter) and ionized air and then with vacuum suction. After that they are returned to an upright position for further processing. The machines automatically reject fallen or upside down containers from the line.

Counting & Filling

We offer you a new generation fully automatic Tablet/Capsule Counting & Filling lines which are able to fill bottles with 100% accuracy. They can reach a capacity of up to 20,000 tablets per minute, depending on the shape (hard capsules, soft gels, irregular shapes, etc.) and the size of the product but also the bottle neck diameter.

After the tablets/capsules are being loaded into the hopper, they are aligned on continuously vibrating trays and then fed to the infrared electronic counting sensors. Once the tablets are being counted they move to the filling heads. Every model has several independently working filling heads and can meet different counting volumes and speed requirements.

In order to identify different problems in products (broken or chipped tablets, black spots, wrong colour, size or shape) advanced inspection systems can be supplied with new tablet counting lines or integrated into existing lines. The highly sensitive vision inspection systems and compact check-weighing systems can detect problems as the tablets/capsules are moving on the trays of the tablet counter. Upon detection, the bottle containing defective product is removed from the line.

The machines feature a self-diagnostic systems that indicate the shortage of products, bottles and caps.

Arcon’s series of electronic counters have many benefits - they are compact, flexible, efficient and easily integrated with any packaging machine. Our counting and filling equipment is designed to meet the highest quality standards of the pharmaceutical and nutraceutical industries and all that comes at very affordable prices.

Capping & Induction Sealing

Arcon supplies a range of semi- and fully automatic in-line cappers capable of handling bottles with different diameters of 20-120 mm at speeds of up to 200 bottles per minute (depending on the shape and size of the cap). Theyoffer solutions for various applications such as screw caps, press-on caps, pilfer-proof caps and aluminum caps.

The semi-automatic models are ideal for small scale production. They are compact, suitable for all kind of caps and offer high efficiency at low cost.

The fully automatic machines ensure perfect cap sealing. They offer many advanced features:

- Vibratory feeder for caps sorting and feeding.

- Rotary capping station with up to 8 capping heads.

- For reliable capping, there is a detection system which will reject bottles without caps or caps that have been incorrectly pressed/screwed.

- Easy change of parts for different types of cap.

- Easy cleaning and maintenance.

- All stainless construction complying with the GMP standards.

For the end of line bottle sealing we offer you a range of induction sealerswhich take place after the containers have already been filled and capped. The induction sealing head creates an electromagnetic field as the bottles pass under it and heats the foil layer under the cap to hermetically seal the container. The sealer can handle different sizes plastic and glass containers with cap diameter ranging between 20-600mm and speed up to 200 bottles per minute. These compact machines have a stainless steel construction, an easy to operate touch screen control panel and a rejection system for bottles without foil.

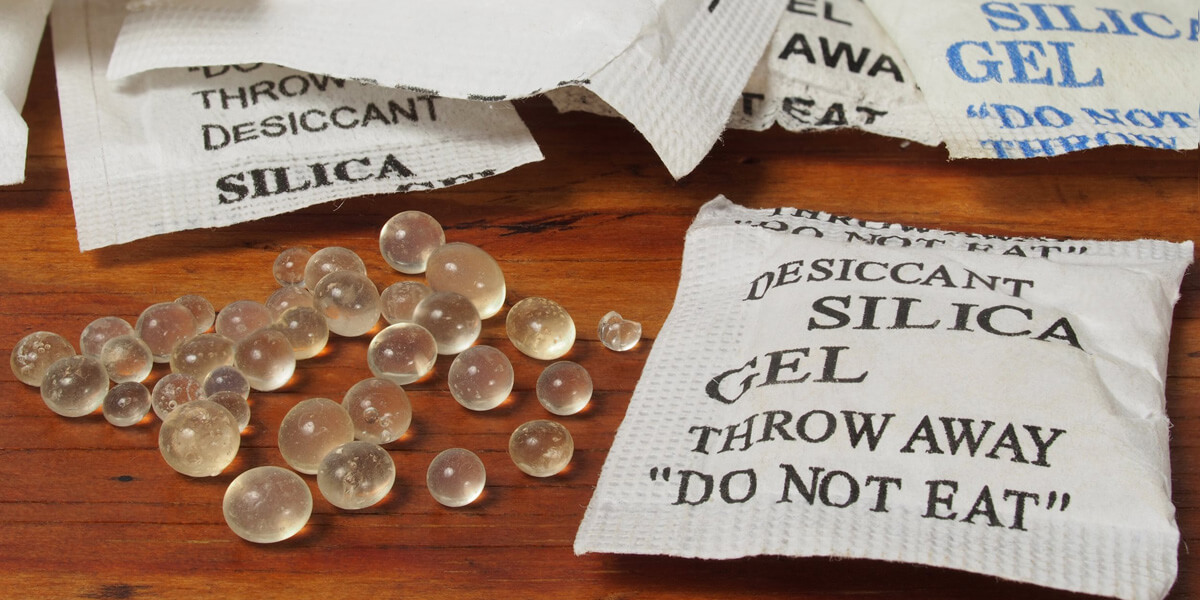

Desiccants Inserting

If you need to protect your product from moisture and to retain its quality we offer you a wide range of bottle inserters which can insert different kind of desiccants - silica gel sachets (pouch); silica gel in canisters; cotton, rayon or polyester coil; polyethylene film and paper. All machines allow multiple desiccants to be inserted into containers (up to a maximum 5 per bottle) without the need to change parts.

The inserters are equipped with verification sensor of desiccants presence and a “no bottle, no insertion” function. They can handle containers with different sizes (approx. diameter 30-100 mm, height 40-200 mm.) at speed up to 200 bottles per minute. The desiccants they insert may also vary in size. You can quickly and easily make all the necessary adjustments through the touch screen control panel.

If you would like to experience the unique quality of our Counting & Filling Solutions, please fill out the contact form below or email us at