- Home

- Solutions / Products

- Processing & Filling

- Tablet / Capsule Automation

- Tablet / Capsule Processing

Arcon supplies an extensive range of equipment for the manufacturing of all types, shapes and sizes of tablets and capsules. For the needs of pharmaceutical, nutraceutical and veterinary industries we offer different capacity Mixers, Coaters, Tablet Presses and Capsule Filling Machines – from laboratory units for R&D, pilot or small scale production batches to high-speed machines for mass production, featuring the latest technologies. All the machines are designed in accordance with the GMP standards, they are independently CE certified and comply with the strictest of quality control criteria in the pharmaceutical industry. The equipment can be used as stand-alone machines or integrated into an existing production line.

Our automatic Tablet/Capsule Bottle Packaging lines that can meet every customer requirements. The solutions offered can handle different shapes and sizes of tablets/capsules at speeds of up to 300 bottles per minute. Various models for Tablet Counting & Filling Equipment are available and can be integrated in a highly effective production line together with some of our wide range of related machines - Cappers, Inserters, Unscramblers / Cleaners and Inspection Systems.

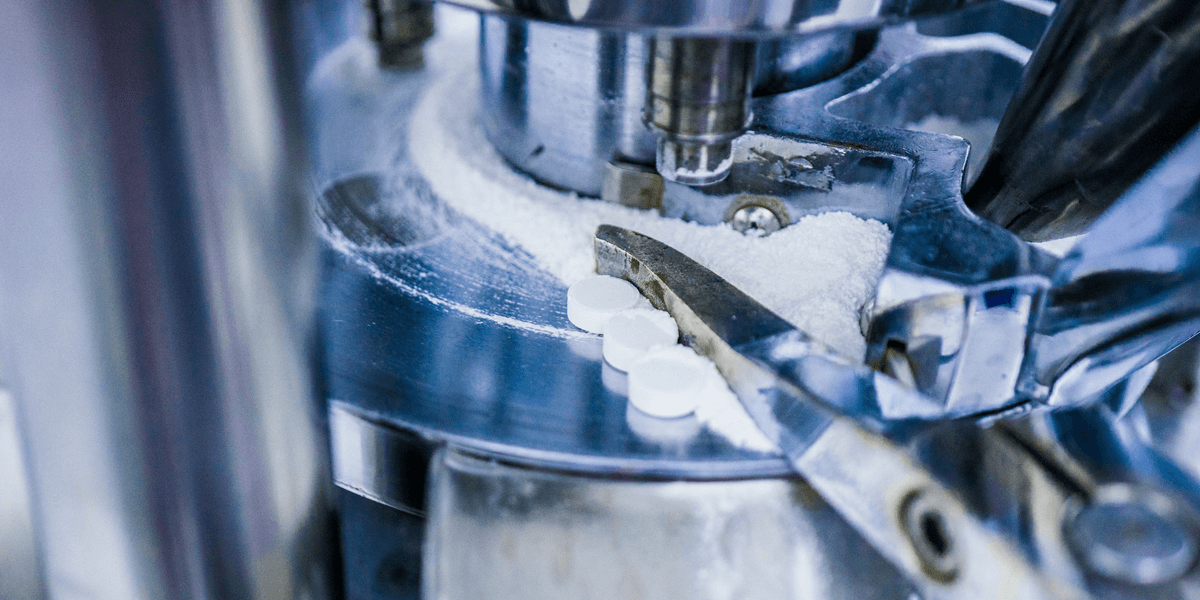

Tablet Pressing

Our product range includes high-speed rotary Tablet Presses which feature the latest technology and meet the requirements of the most demanding customers from pharmaceutical, nutraceutical and chemical industrie. All shapes, sizes and types of tablets can be pressed, including oblong shaped, single and double-sided, triple or multi-layered and effervescent tablets.

The range caters for all process requirements from small-scale laboratory research applications right up to full scale production. Depending on the tablet size and number of layers required, speeds of up to 570 000 tablets per hour can be achieved.

The main features of the production Tablet Presses are:

- Capacity up to 570,000 single layer tablets per hour.

- Run multiple formats – removable turret.

- Quick product setup.

- Automatic tablet weight control system.

- Defective tablet rejecting system.

- Industrial standard PLC control system with touch screen.

- Easy maintenance, assembly and disassembly.

- GMP compliant design.

- Cost effective.

Every Tablet press can be delivered with additional options including Tablet Deduster, Metal Detector, Powder Loader, Tablet Compression Tooling and others.

Tablet Coating

We offer a range of highly effective Tablet Coating Systems with a proven coating and drying technology. Depending on the product density, output capacities of up to 600 kg can be reached. These proficient systems are ideal for all tablet coating requirements - sugar, organic film and liquid film coating.

Designed and built in accordance with GMP standards, the exterior of the coating system is fabricated in stainless steel and offers an easy-to-clean solution for customers in the pharmaceutical industry.

The punched hole pan maximizes drying efficiency by increasesing the distribution of air through the tablets and thus the coating time is reduced.

The other great benefit of the Coaters are the mixing baffles, allowing smooth movement of the tablets throughout the pan, which guarantees fast coating, decreased tablet damage and uniform film coverage.

The main features of the Coating and Drying Systems are:

- PLC control for easy operation.

- Process data can be recorded.

- Auto system Cleaning in Place is available.

- Explosion proof system.

- Easy maintenance and cleaning.

- Auto discharge system.

- Cost effective.

Capsule Filling

Arcon supplies a wide range of high quality semi- and fully automatic Capsule Filling Machines, designed to fill hard gelatin capsules with powder or pellets. The different models offer production capacities up to 120,000 capsules per hour and various filling combinations: powder or pellets only, powder plus pellets, two pellets, or two pellets plus powder and many other product combinations. The modular design allows quick parts change over and easy access for maintenance and cleaning.

The main features of the Capsule Filling Machines are:

- Capacity up to 120,000 capsules per hour.

- Vast range of filling options.

- Precise filling.

- Range of capsule sizes 00,0,1,2,3,4.

- Faulty capsule rejection station.

- Easy maintenance and cleaning.

- All stainless construction.

- CE marking and GMP compliance.

- Cost effective.

Mixing-Granulating-Fluid Bed Systems

Arcon supplies highly efficient Mixer Granulators and Fluid Bed Systems for the pharmacy and instant food production that fully comply with the strict GMP standards. They are suitable for laboratory use, pilot and large scale production.

The multifunctional Fluid Bed Systems can perform granulating, drying and coating processes in a single machine, saving floorspace and reducing production time. Our complete range offers different working capacities from 1 kg up to 600 kgs/batch. Their excellent heat transfer and speed of drying guarantee short drying time even of thermo-sensitive products.

Depending on the product and the type of coating the systems can be top, bottom or side spray type.

The Mixer Granulators also combine multiple processes into a single machine (dry and wet powder mixing plus granulation). The fully automatic, closed-type operation reduces the risk of contamination and has many successful references across a variety of applications in the pharmaceutical industry. With machines to accommodate working volumes of 8- 480 litres and average working batches of 2 - 200 kg, Arcon is sure to supply a solution that meets your requirements.

The main features of the Mixer Granulators and Fluid Bed Systems are:

- Fast and effective drying even of thermo- sensitive products.

- Homogeneous granules and uniform product quality.

- Easy to operate and maintain.

- Dust free operation.

- Easy cleaning –water cleaning of the inside can be done.

- GMP compliant design.

- Cost effective.

If you would like to experience the unique quality of our Tablet & Capsule Processing Solutions, please fill out the contact form below or email us at

Industries:

Pharmaceuticals / Cosmetics, Food & Beverages, Plastics / Chemicals / Detergents.